Automotive paints measurements

Painting is a very important processing step during automotive manufacturing. Paint coats perform a number of important functions, not only by giving distinct colours to a vehicle, but also to provide crucial protection from UV radiation, corrosion, scratches and harmful chemicals.

Conventional methods to measure the thickness of car paint layers such as magnetic gauges, eddy current measurements and ultrasound testing all require direct contact between the measurement sensor and the painted car surface. These measurement techniques can only cover a limited number of sampling points on selected cars and hence lack the capability to identify paint defects, monitor wet to dry processes and map the thickness distribution of the paint layers over a larger surface of the vehicle. In addition, only the ultrasound technique is capable of resolving the multiple paint layers whereas the other techniques merely measure total thickness of the film build.

This project was carried out in collaboration with TeraView Ltd. and Aston Martin

Recent developments of terahertz time-domain spectroscopy have opened up a number of opportunities for non-destructive testing applications across a large range of fields.The aim of our research project is to develop novel terahertz sensor for automobile paints thickness measurements and quality evaluation in real time.

Paint thickness extraction

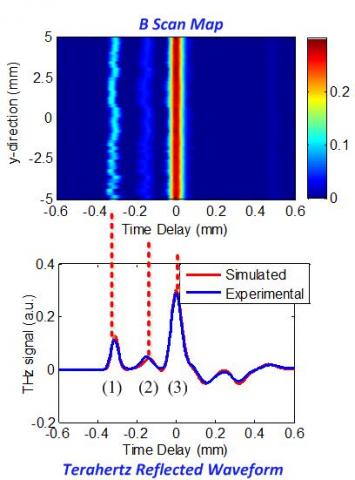

We propose to use terahertz pulsed imaging (TPI) as a novel tool to measure the thickness and quality of up to four layers of car paint on both metallic and non-metallic substrates. Using a rigorous one-dimensional electromagnetic model for terahertz propagation in a multi-layered medium, simulated reflected time-domain terahertz waveform can be calculated. The thickness of each coating layer was then extracted by fitting the measured reflected waveform with the simulated waveform by iterating the initial guessing thickness and minimizing the residual sum of squares between the measured and simulated waveform using the least square method.

The B-scans show individual waveform as a function of vertical scan position. Color lines in the B-scan map represent the interface between different paint layers. The deconvolved time domain reflected waveforms is from a single point on the sample. The first, second, and third positive reflection are from the air-clearcoat, basecoat-primer1, and electrocoat-metal boundary.

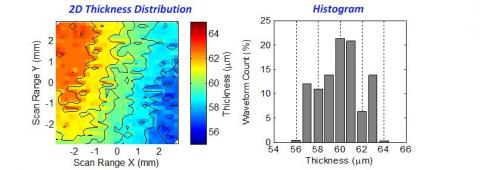

Paint layer uniformity

The big advantage of TPI is that the technique is capable of measuring not only an average thickness but also to resolve the homogeneity of the coating thickness across the entire surface of the sample to determine the uniformity of the paint layer and detect paint defects. Terahertz measurements were made over a two-dimensional area and therefore a map of thickness as a function of position is generated. The histogram clearly indicates distinctly thickness variations over the entire surface, which is critical factor to determine the quality of the paint layers.

Key publications

K. Su, Y.C. Shen, and J.A. Zeitler, Terahertz sensor for non-contact thickness and quality measurement of automobile paints of varying complexity, IEEE Transactions of Terahertz Science and Technology, doi:10.1109/TTHZ.2014.2325393, 4, 432-439(2014).

I.S. Gregory, R.K. May, K. Su, and J.A. Zeitler, Terahertz Car Paint Thickness Sensor: Out of the Lab and Into the Factory, 39th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), 2014.

Funding

Funding through Innovate UK and EPSRC:

http://gtr.rcuk.ac.uk/project/AF3E2CEB-584B-4523-8B67-C1877CA7B503